EN

Vertalen:

Choose your language at the right edge of the site! →

EN

EN

Vertalen:

Choose your language at the right edge of the site! →

EN

Ingersoll Rand / ARO has been a household name for 80 years and is therefore a leading pump brand. We supply these pumps to loyal customers, because we have been working together for almost 50 years.

The PDO series diaphragm pumps are delivered by a five-year warranty on material and workmanship.

Ingersoll Rand Industrial Technologies offers products, services and solutions to improve the efficiency and productivity of commercial, industrial and process customers. Innovative products include air compressors, components of air systems, tools, pumps, material and fluid treatment systems and micro turbines.

Metallic diaphragm pumps from Ingersoll-Rand ARO are adaptable to various application requirements. These pumps are available in the following port sizes: 1/2", 3/4" 1", 1 1/2", 2", and 3", with flow rates ranging from 49 to 1,040 litres per minute.

Materials of construction: Aluminium, RVS, Cast Iron, and Hastelloy

Diaphragm material: Santoprene®, Nitrile, PTFE, Viton®, Hytrel®, and Medical grade Santoprene

Plastic diaphragm pumps from Ingersoll-Rand ARO can increase fluid applications. These pumps are available in the following port sizes: 3/8", 3/4", 1/4", 1/2", 1", 1 1/2", and 2", with flow rates ranging from 17 to 696 litres per minute.

Materials of construction: Polypropylene, Kynar (PVDF) and Groundable Acetal.

Diaphragm material: Santoprene®, Nitrile, PTFE, Polyurethane, Viton®, Hytrel®, and Medical grade Santoprene®

ARO, Owner of the "Unstallable" Air Valve Design

As relevant today as it was the day it came to the market, ARO is still the sole owner of the technology and the title: Unstallable. ARO uses no magnets, springs, reset buttons, or other secondary actuators to ensure pump shifting - only air.

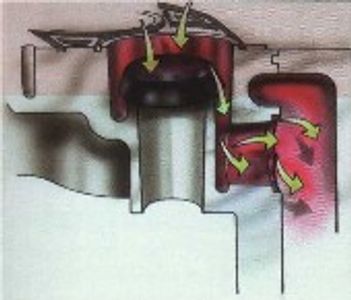

ARO’s patented “unbalanced” major air valve has constant air pressure applied to its small end. This assures that the pump resets. Competitive designs lose their signal during every shift, making them vulnerable to stalling.

To reverse the valve, air pressure is supplied to the larger end of the valve, allowing the valve to shift - note that constant air pressure continues to be applied to the small end.

Following closely on the heels of the pump stall-out is the infamous freezing problem inherent in most diaphragm pumps. At Aro, the ice age has been over since the introduction of our unique, enlarged “Quick Dump™” patented air exhaust valve, which diverts air exhaust from critical, ice-prone passages. Available on the ARO 2" (Balls & Flap) and 3" diaphragm pump models.

When the main valve opens and pressurises the diaphragm air chamber, the Quick Dump operates like a normal air passage and admits air into the diaphragm’s air chamber.

When the main valve is ready to exhaust, the Quick Dump diverts all of the cold/wet exhaust air coming from the diaphragm air chamber away from the main air valve, avoiding ice formation in the critical valve passages.

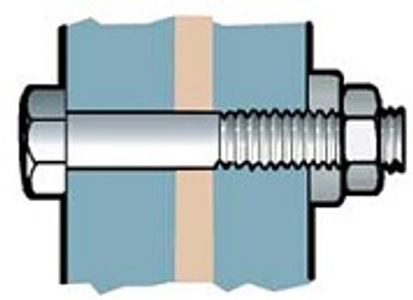

For Safety, Reliability, and Ease of Assembly: Bolted Is Better.

ARO diaphragm pumps feature bolted construction to avoid the proven problems created by clamp band type pump fasteners. These include material spills and leaks, bolt loosening, and breakage due to poor joint integrity, and difficult reassembly.

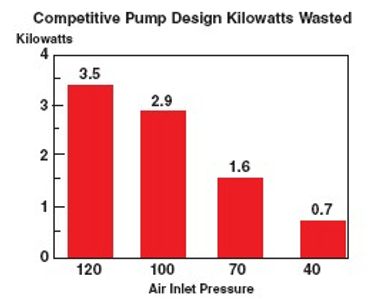

The close fitting air valve designs used on competitive pumps allow air to bypass continually, which wastes air even when not pumping!

Hethon Nederland B.V.

Vlijtstraat 47, 7005 BN Doetinchem The Netherlands KVK 50159542

T: +31(0) 74-2500555 ■ E: info@hethon.nl ■ W: www.hethon.nl

This website uses cookies. If you continue to use this site, you agree to our use of cookies.